Precision Multi-Axis CNC Machining

For over seven decades Imperial Machine & Tool Co. has been known for providing the highest quality in machining and fabricating. From the early days of manual machines through today's multi-axis CNC precision machine tools Imperial has been in the forefront of complex machined components, structures and weldments. We've built our reputation on successfully and reliably delivering complex machined components to customers all over the world.

Machined Titanium components for the M777 Ultra-Lightweight Howitzer Cannon

To do so we employ industry’s most technologically advanced CNC machine tools. More importantly we employ and train talented individuals capable of meeting the high standards we set. We program all of our machine tools off-line using Virtual Gibbs CAD software. Imperial does not program at the machine tool, this ensures effective management of program revisions, as well as provides consistent output on succeeding runs.

The vast majority of our machine tools are set up with Renishaw Touch Probing systems and through the spindle coolant. These features allow us to set up work and perform operations unattended. Through the spindle coolant enables us to cut very challenging materials as well as perform “deep” work on bores and “hogouts.”

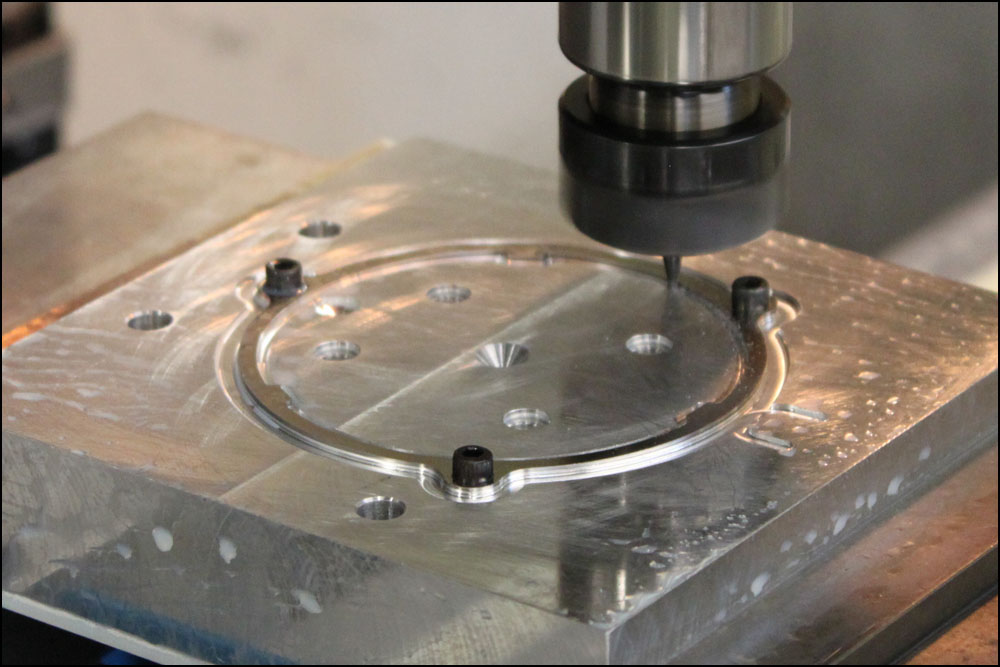

Imperial is a detail oriented shop and as such we attack our work in an orderly fashion. This approach is why we employ a common baseplate on all our machine tools. This commonality allows our CNC programmers to plan their work with the knowledge that tooling holes and patterns will be present on any machine tool the work is run on. At Imperial we believe commonality in approach and commonality in manufacture leads to commonality in results. We are known for our very high quality work and consistency in our products. If we’ve learned anything over the past 75 years it is that those with the highest quality are those that thrive and grow in our industry.

Precision machined semiconductor component.

Exploring our equipment list, the reader will note that we favor Haas machine tools. We have several dozen of them and use them to cut some of the most challenging materials to very close tolerances. Imperial has extensive capabilities in 3, 4 and 5 axis machining of large and small workpieces. While it is certainly work-specific, we regularly hold tolerances of .0002” in machining envelopes as large as 30” X 40” X 84”.

A look inside our 30,000 sq-ft facility. We pride ourselves on keeping things clean and organized, and welcome customer visits.

We have the experience, equipment, and resources to handle even the most challenging machining projects, but our commitment to customer service is the real key to our long-term success. We are willing to go to any length to make sure our customers are completely satisfied.

Imperial is always looking for talented folks looking to build a career, particularly experienced CNC Machinists who can program, set-up and run close tolerance work. If interested, please visit our career opportunities page.

If you have questions about our specific capabilities please contact us, we'd be happy to answer your questions.