The Vortic Watch Company produces some of the most beautiful watches in the world.

They restore antique, American-made mechanical watch movements and house them in modern 3D Printed Titanium cases. The results are stunning, and we're proud to be their Metal Additive Manufacturing partner.

The "Springfield 041", a recent offering from Vortic's American Artisan Series.

The Golden Age of Mechanical Watches

Many folks don't know it, but from the late 1800s through the 1950s America was the preeminent technology leader and producer of accurate, high-quality pocket watches.

This leadership position was fueled by the rapid expansion of the American railroad network and the growing need to keep accurate time. Train conductors relied exclusively on high-quality pocket watches to keep trains on schedule as they traveled across the country.

Thanks to innovative manufacturing technologies developed during the industrial revolution, high-quality watches were produced by the millions.

Even compared to modern Swiss-made mechanical watches, the movements manufactured during this "golden era" are truly outstanding.

The movements are of such high quality that even after 100 years many simply need a little patience from a skilled individual to make them run like new again.

Born from the Ashes

Unfortunately, pocket watches fell from popularity and many of these fine timepieces were cast aside and forgotten. Many watches were sold to jewelers for scrap value to recover the gold used to make the case. These orphaned mechanical movements were tossed into bins to collect dust, or worse, sent to the landfill.

That's where the story of Vortic Watch company begins.

Cases were commonly made from 14k gold

Vortic is Born

The founders of Vortic thought it was a tragedy to see these fine American-made watch movements end up in the landfill. This spurred a simple business idea: Use modern manufacturing technology to make custom cases for these orphaned watch movements.

They made a few prototypes to validate their idea, and the watch enthusiast community responded very well.

A customer in Texas trying on their Vortic watch for the first time

Vortic officially opened for business in 2013, on a mission to preserve a piece of American manufacturing history while creating heirloom quality wrist watches that will survive the next 100+ years.

3D Printing Titanium Watch Cases

Vortic restores mechanical movements from nearly all of the great American watch companies. Consequently, they must manufacture cases for many different sizes, makes, and models of antique watches. This variability poses problems for traditional manufacturing methods.

Vortic needed a manufacturing method that was flexible enough to produce different case designs, at relatively low volume, at a competitive price. They found a solution in Metal Additive Manufacturing (AM).

Metal AM enables the fabrication of "infinite" designs on the same tool. The only thing that needs to change is the CAD file. Vortic can easily fabricate bespoke designs, even on the same build plate, and quickly implement design changes between batches.

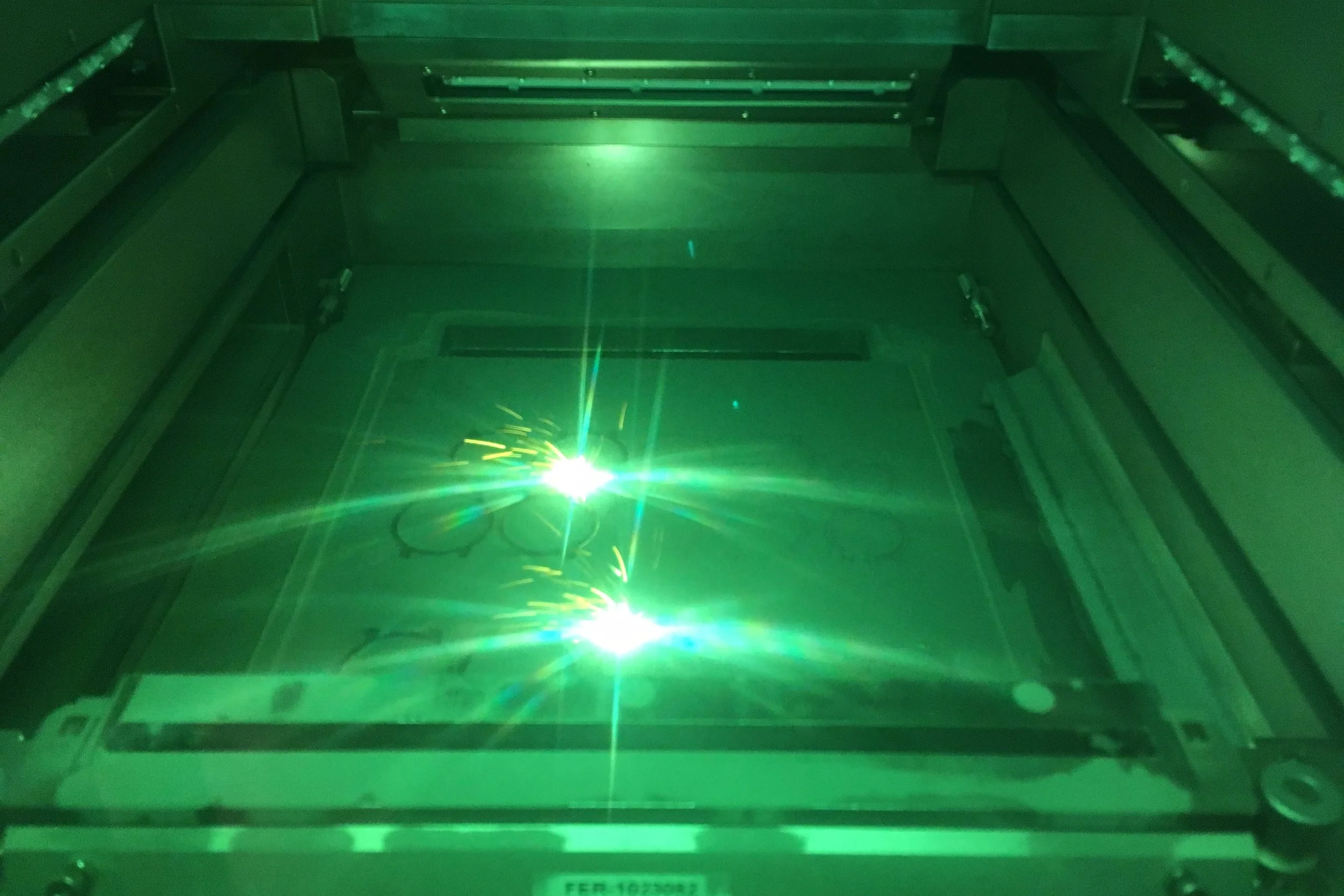

Vortic watches being fabricated via Metal Powder Bed Fusion on Imperial's SLM 280 HL Twin-Laser

Imperial manufactures all of Vortic's Titanium-printed cases right here in our Columbia, NJ facility. We're honored to play a role in preserving these fine mechanical timepieces from a golden age of American manufacturing.

A fresh batch of 3D Printed Titanium watch cases, manufactured by Imperial Machine & Tool Co. in Columbia, NJ

Beautiful American Made Watches

It's hard to believe the beautiful and intricate machining on all these antique mechanical movements was carried out over 100 years ago. The level of craftsmanship is truly incredible, and was achieved by a skilled machinist using only manual machine tools.

A beautiful Waltham watch movement made in 1906, click to enlarge

Vortic is currently the only company in the world offering watches that are truly American made, down to every last spring, pin, and gear.

Tradition Meets Innovation

Vortic is preserving an important part of United States history. Their watches are proof that a truly modern and beautiful watch can be created while still honoring our manufacturing roots. These watches are once again heirlooms that can be passed down from generation to generation.

Vortic Watch Company's headquarters in Fort Collins, Colorado

If you'd like to see more of Vortic's watches, you can find more information on their website www.vorticwatches.com